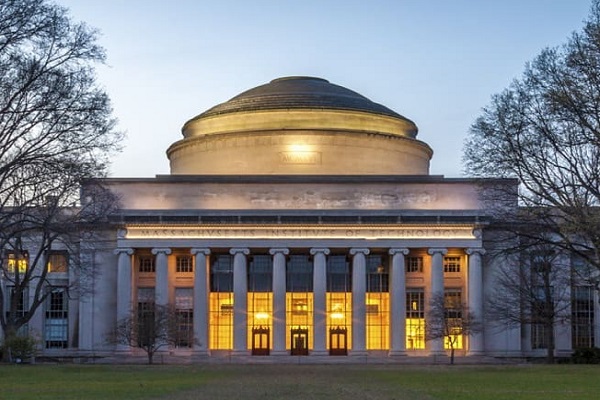

Massachusetts Institute Of Technology Lab Develops Propulsion Systems For Nex-Gen Aircraft

In 1941, the National Academy of Sciences appointed a committee to assess the use of gas turbine engines — which use heat released during fuel combustion to produce thrust for propulsion — in aviation. The group of luminaries concluded that due to the temperature limitations of existing materials, gas turbines did not have much of a future in propelling airplanes.

However, “Unknown to the committee, the first jet engine was already successfully run in Germany in 1940: the Junkers Jumo,” says Professor Zoltán Spakovszky, director of the MIT Gas Turbine Laboratory (GTL) and the T.A. Wilson Professor in Aeronautics and Astronautics. Although the committee had correctly identified the temperature limitations, “the German engineers and designers redefined the problem and introduced turbine cooling,” he explains.

The Junkers Jumo, the world’s first turbojet engine in production, was put in operation during World War II, while separately, Sir Frank Whittle had been leading progress on the development of the turbojet engine in Great Britain. With the United States falling behind Germany and Britain in developing turbojet engines, Professor Jerome C. Hunsaker had the vision of establishing a laboratory dedicated to gas turbine propulsion at MIT. Hunsaker, an aviation pioneer in his own right and member of the National Advisory Committee of Aeronautics, gathered funds and support from six U.S. industries and the U.S. Navy to get started.

On Oct. 7, 1947, the GTL, led by Professor Edward Story Taylor as its founding director, officially launched with all major U.S. aviation and aircraft companies of that time in attendance at the opening ceremony. Over the course of 75 years, the GTL, now housed in the Department of Aeronautics and Astronautics, has been at the cutting edge of applied research. It continues to do so by delivering “new perspectives on integration of propulsion systems with new aircraft concepts and high-impact collaborative projects cutting across disciplines,” Spakovszky says.

To describe the work of laboratory, Professor Edward Greitzer, a former GTL director and the H.N. Slater Professor in Aeronautics and Astronautics, quotes former prime minister of Singapore Lee Kuan Yew, who spoke of not “perfecting the known,” but rather reaching for the unknown. “That’s what we have always tried to do at the GTL,” Greitzer says. “We do our best to think strategically about things we could do that would not only be intellectually interesting but would also have an impact.”

The GTL “is still going very strong, tackling new and different challenges,” Spakovszky says. “Today, we’re not only working on the propulsion system, jet engines, and power plants, we’re also working on integrating jet engines into aircraft and on forward-looking challenges like electrification of aviation.”

In the early years, projects focused on one discipline and addressed one specific problem, Greitzer points out, but today’s GTL works on “problems with larger scope and scale, cutting across disciplines and sometimes organizations.” For example, a project working on a conceptual design of a fuel-efficient aircraft led to a test in a large wind tunnel, at a NASA facility.

Equally important, Spakovszky adds, is the lab’s focus on industry. True to its roots, the GTL continues to work on “projects that don’t just go into theses and sit on the shelf; they actually move the needle and start with real applications in industry,” he says. Super-high-pressure ratio compressors for carbon sequestration and ultrashort aeroengine inlets to reduce fuel burn are examples of the many different industry-focused projects that the GTL has worked on.

Fostering excellence, passion, and collaboration

Over the past three-quarters of a century, close to 500 students have called the GTL their academic home. In addition to being steeped in academic rigor, students came away with technical communication skills, says Borislav “Bobby” Sirakov SM ’01, PhD ’04. The ability, “developed at the GTL, to summarize and explain a complex topic in simple words has served me well in my career,” he states.

Andras Kiss ’13, SM ’15, PhD ’21, worked at the GTL from his sophomore year in Course 16 until he completed his doctoral degree in aerospace engineering. “The first thing that Zolti or Ed would say when you wrote a report or made a presentation was ‘answer the Heilmeier questions [a series of questions addressing risks, costs and more] in plain language,’ Kiss laughs, “It was all about distilling your work into very approachable, clear language so you know exactly what you’re trying to do. Otherwise it’s very easy to hide behind detail.”

Kiss has many fond memories of the GTL, including the time he spent designing the electrical and fuel systems for a turbofan engine and having it work smoothly after 18 months of effort. “It was a real thrill, seeing the engine start up for the first time,” he remembers.

Phil Mullan SM ’59, ME ’62, ScD ’64, who majored in mechanical engineering at MIT while working in the GTL, loved the academic rigor. “The lab environment was very invigorating for me because the other research assistants were really bright people,” Mullan says. “They came from different backgrounds and had lots of good ideas to share and were always willing to help.” He remembers looking forward to the midmorning and midafternoon coffee breaks in the library.

According to Spakovszky, ideas that pushed the boundaries of so-called conventional wisdom have been an important differentiator of the GTL. Two research initiatives in this regard have been Micro-Engines, shirt-button-sized gas turbine engines for portable power made using computer chip manufacturing, and the Silent Aircraft Initiative, focused on the conceptual design of an aircraft whose noise would be imperceptible outside airport boundaries.

This approach was also evident when approaching challenges earlier in the lab’s history, like finding the original drive system for the De Laval wind tunnel and air system. Not to be confused with MIT AeroAstro’s Wright Brothers Wind Tunnel, the reconfigurable De Laval wind tunnel is located within Building 31 and provides air to various test facilities. “The logistical challenge was getting a motor to run the compressor,” Spakovszky says. “It turns out that the USS Halibut, a Gato-class submarine, had run ashore and was decommissioned in New Hampshire in 1945. Eddie Taylor bought the motor drive system out of that submarine and put it here in 1947. We operated that equipment until we renovated a few years ago (in 2017) and now have a new electric motor to drive the De Laval air system.”

According to Greitzer, there have been pleasant technological surprises along the way since he joined the GTL (from Pratt and Whitney) in 1977. One of these was the Silent Aircraft Initiative. “My expectation was that we’d have a trade-off of performance — fuel burn for noise,” Greitzer says. “But we found that if you think about opening up the design of the aircraft … you don’t have to make those compromises and you can get both less noise and improved fuel burn performance.”

Celebrating a roaring future

In his 1947 welcome speech inaugurating the lab, Taylor said: “It hardly seems necessary to stress the growing importance of the gas turbine as a prime mover.” In the speech he also referred to the GTL as a “a new laboratory specifically designed for research in problems encountered in gas turbines.”

On Oct. 7, 2022, 75 years later to the day, Spakovszky addressed a room full of more than 140 alumni, industry members, and academic luminaries who came together from all over the world to return to campus and celebrate the historic milestone for the GTL. Mullan — with his grandson, an engineer with Pratt and Whitney, in tow — Sirakov, and Kiss were among the laboratory alumni in attendance.

“The challenges are different now compared to 75 years ago, but the way we do research and the way we collaborate has not changed. Today, we’re looking at electrifying aviation and working with new fuels like hydrogen,” Spakovszky says. “The bottom line is that our name has not changed, we’re still the Gas Turbine Lab, but we’re doing more than gas turbines, and addressing different aspects of the field.”

The lab’s invigorating environment and a passion for gas turbine technology were on full display at the celebrations where attendees were delighted to catch up with old friends and mentors and go down memory lane while touring the GTL’s renovated facilities to learn more about the latest research and even view a Junkers Jumo 004 engine on display, an emblem of the field’s history embedded in the present.

While 2022 marked an important milestone in the history of the GTL, Sirakov believes that the lab will always be at the forefront of advancements.

“I was very happy to see so many new test rigs and experimental projects going on,” he says. “I am proud of the long history of the lab, the long list of contributions to the field, and the powerful beginning with all the aerospace leaders attending the [launch]. It’s remarkable that after so many years the MIT GTL lab is still very relevant to the fields of aeronautics, space, and automotive [research] and to all of the new and exciting horizons like electrification and clean energy.”

Greitzer agrees. “The feeling that came through at the 75th anniversary celebration is that the Gas Turbine Lab is a special place, it’s distinctive and it’s different,” Greitzer says. “We continue on our voyage of discovery to learn the unknown.”