Smaller, lighter lithium-sulphur battery lowers costs and improves recycling options

Researchers at Monash University have developed a new lithium-sulphur battery design with a nanoporous polymer-coated lithium foil anode that reduces the amount of lithium required in a single battery.

With the transition to renewable energies a global mission, the need for more sustainable energy storage solutions is becoming critical.

In their recent paper PhD student Declan McNamara, Professor Matthew Hill, and Professor Mainak Majumder of Monash Engineering, with Dr Makhdokht Shaibani of RMIT University, outline how applying the nanoporous polymer directly onto the lithium foil anode has created a new battery design that uses less lithium, has more energy per unit volume, lasts longer and will be half the price of lithium-ion batteries.

Lithium-sulphur (Li-S) batteries are an emerging energy storage technology that utilise metallic lithium and sulphur to deliver more energy per gram than lithium ion batteries. While the Li-S batteries are highly efficient, the process of finding, extracting and transporting lithium leaves a significant environmental footprint, so using as little lithium as possible remains important.

Li-S batteries also have their limitations. Typically they contain a lithium anode (negative electrode) and sulphur cathode (positive electrode) with a separating layer. When the battery charges and discharges, large amounts of lithium and sulphur are reacted with one another, placing the lithium metal under a lot of strain.

PhD student and lead researcher Declan McNamara of Monash Engineering said the thin polymer coating on lithium significantly improved the number of times the battery could be cycled.

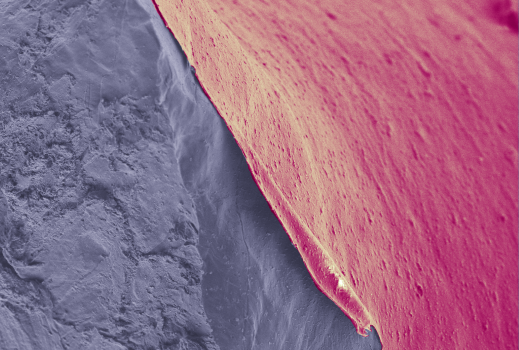

“The polymer contains tiny holes less than a nanometre in size – one billionth of a metre – which allow lithium ions to move freely while blocking other chemicals that would attack the lithium. The coating also acts as a scaffold for lithium, and helps it charge and discharge repeatedly.

“Metallic lithium is a bit of a double-edged sword. Lithium is packed full of energy, but in a bad battery, this energy is wasted on side reactions. On the other hand, if the energy is channelled correctly, it can make some incredible energy storage devices that are easier to make. This coating is a step towards highly efficient, easily manufactured Li-S batteries,” Mr McNamara said.

The new design does not require nickel or cobalt, removing the need for minerals that have a significant environmental and social cost.

Professor Majumder said these developments are promising steps towards more widespread adoption of Li-S batteries and other lithium metal-based energy storage systems.

“Li-metal protection technologies will become crucial in our quest towards energy dense and sustainable batteries of the future. The study establishes a new framework to protect Li-metal from rapid decay or catastrophic failure which has been an achilles heel for Li-S batteries,” he said.

Professor Hill said the technology could make an immediate impact.

“The market for electric vehicles, drones and electronic devices is on a steep growth pattern and this research is commercially ready for manufacturing to support that growth. Producing more economical and environmentally sensitive battery options in Australia would be a great use of this technology, and we look forward to working with commercial partners to develop and manufacture this technology,” he said.