Tiny Bacterium, Big Impact: Potential Breakthrough in Rare-Earth Processing Discovered

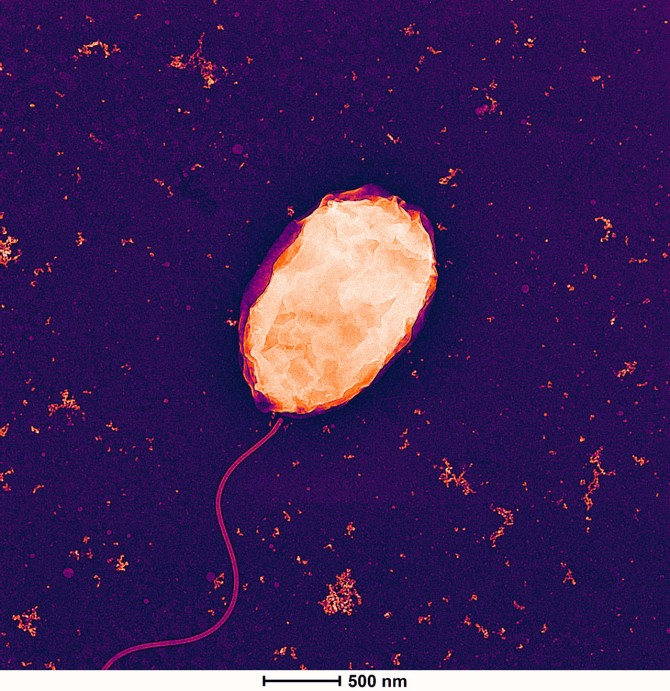

A tiny, hardworking bacterium – which weighs one-trillionth of a gram – may soon have a large influence on processing rare earth elements in an eco-friendly way.

In a new study, Cornell scientists show that genetically engineering this bacterium could improve the efficiency for the purification of elements found in smartphones, computers, electric cars and wind turbines, and could even boost global economic supply chains.

Vibrio natriegens, the bacterium, offers a sustainable method – called biosorption – to extract valuable and needed elements rather than use older, polluting solvent-heavy methods.

The Cornell research, “Multiple Rounds of In Vivo Random Mutagenesis and Selection in Vibrio Natriegens Result in Substantial Increases in REE Binding Capacity,” was published Dec. 6 in Synthetic Biology, an American Chemical Society journal.

“Traditional thermochemical methods for separating lanthanides are environmentally horrible,” said Buz Barstow, assistant professor of biological and environmental engineering in the College of Agriculture and Life Sciences, the corresponding author. “It’s difficult to refine these elements. That’s why we send rare earth elements offshore – generally to China – to process them.”

Doctoral student Sean Medin and Anastacia Dressel ’24 led the research to genetically engineer a strain of Vibrio natriegens to increase its ability to biosorb – or extract – rare earth elements.

The researchers changed the genome of Vibrio natriegens with a plasmid called MP6, which introduces errors into the genome and then screened the mutants for increased biosorption of rare earth elements. “Given the ease of finding significant biosorption mutants, these results highlight just how many genes likely contribute to biosorption,” he said, “as well as the power of random mutagenesis in identifying genes of interest and optimizing a biological system for a task.”

Rare earth elements play a critical role in modern society. They are found in computers, batteries and clean energy technologies. In early 2021, the White House ordered an assessment that later found an over-reliance on the foreign sources and adversarial nations processing the elements, posing national and economic security.

Vibrio natriegens – and a growing array of bacterial tools – offer a way to safely bring rare earth elements and minerals processing back to the U.S. For example, at the Mountain Pass rare earth element mine in California, near the tip of the Nevada border, biological processing could bring this mine back to robust domestic productivity, Barstow said.

“This new work gives us a shot to leapfrog thermochemical methods,” Barstow said. “We can engineer this and other bacterium and because we don’t need to purify proteins, we can operate this kind of system much more cheaply than competing biological processes.”

The U.S. no longer has expertise in thermochemical processing methods, Barstow said. “For purifying rare earth elements, we’re now left with competing green methods” he said. “So even if we wanted to old thermochemical methods, we probably couldn’t. We no longer know how to do it.”

Barstow said: “We are being forced to innovate our way out of this problem.”

In addition to Barstow, Medin and Dressel ’24, the co-authors are: David A. Specht, postdoctoral researcher; Timothy J. Sheppard, research scientist; Megan E. Holycross, assistant professor, Cornell Engineering; Matthew C. Reid, assistant professor (ENG); Esteban Gazel, the Charles N. Mellowes Professor in Engineering (ENG); and Mingming Wu, professor (CALS).

Barstow is a faculty fellow at the Cornell Atkinson Center for Sustainability and Medin will join REEgen, a startup company in Cornell’s Praxis Center for Venture Development.

This research was supported by Cornell Presidential Life Sciences Graduate Fellowship, the Cornell Energy Systems Institute, the Cornell Engineering Learning Initiative, the Burroughs Welcome Fund, an Academic Venture Fund award from the Cornell Atkinson Center for Sustainability, a Cornell 2030 Project Fast Grant, and a gift from Mary Fernando Conrad ’83 and Tony Conrad.