AI-Powered Machines Test New Materials, Reducing Human Effort

We are living in a material world.

In the face of an intense period of global evolution, including climate change, aging populations and an increased need to conserve resources such as food and water, the fate of the future may depend on the development of innovative materials.

Yanjie Fu, an associate professor of computer science in the School of Computing and Augmented Intelligence, part of the Ira A. Fulton Schools of Engineering at Arizona State University, and his colleague, Alix Schmidt, a senior data scientist at Dow (NYSE: DOW), were recently awarded a Grainger Foundation Frontiers of Engineering Grant by the National Academy of Engineering, or NAE, to use artificial intelligence to help engineer new materials.

“Though we may rarely notice it, materials science has an enormous impact on our daily lives,” Schmidt says. “By the time I get to work in the morning, I have already interacted with hundreds of materials innovations. My daily sunscreen lotion doesn’t leave me feeling oily, my car doesn’t rust despite the salty Michigan winter roads and my phone forgives me for dropping it in the parking lot.”

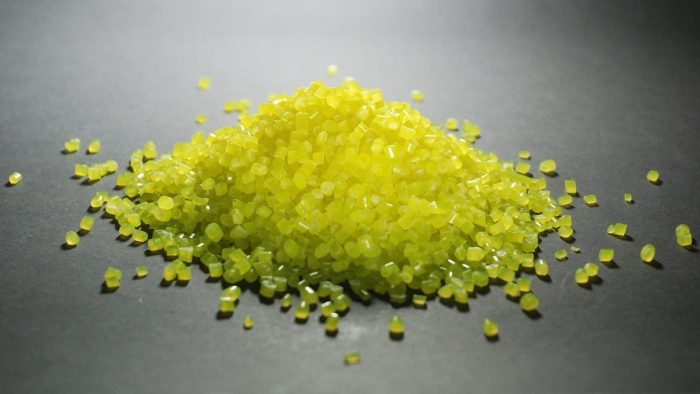

The grant is designed to help the researchers increase the speed and decrease the cost of developing polymers or inorganic materials by tapping the power of artificial intelligence, or AI. New materials discovered by AI can be developed to have unique properties and have the potential to make airplanes safer, food storage better and military technology more affordable.

More sustainable processes save time and money

Right now, the process of making new materials often involves, well, physically making new materials. Engineers must typically produce new types of stretchy rubber, heat-resistant plastic or more durable forms of glass, testing each, sometimes by trial and error, until they find something that can be mass-produced.

For this project, Fu and Schmidt will employ a type of AI called deep machine learning in which computers run software programs that enable them to learn by example in a way that models the human mind. The researchers will use large libraries of historical data from the field of material science to essentially train machines to make virtual models of new materials, run simulated tests and provide key information to scientists.

“The artificial intelligence system will use historical data to learn about patterns in material compositions, which will eliminate the need to test each material one by one,” Fu says.

The team’s efforts will also create a more environmentally friendly, sustainable manufacturing pipeline, as it will become less necessary to consume resources testing formulations that will likely never be utilized.

Fu says, “The result will be that only the promising options will be made and labs can spend their money on the materials most likely to work.”

Dow data drives deep learning

The pair of researchers initially connected at the U.S. Frontiers of Engineering Symposium last year. They began to discuss ways to collaborate. As Fu described his background in computer science, Schmidt theorized that her work at Dow — especially the company’s manufacturing expertise and massive material science library — could be helpful. They decided to team up to develop an effective machine learning system.

Founded in 1897 by Herbert Henry Dow following his discovery of a new method of extracting bromine from brine, Dow now produces materials that support a wide range of applications, from food packaging to athletic shoes to beauty products. Their breadth of knowledge makes the company ideal to work with for this type of research project.

Thanks to these machine learning systems, we’ll be in the kitchen with only the ingredients likely to make tasty dishes.

Yanjie FuAssociate professor of computer science, School of Computing and Augmented Intelligence

“It’s a challenge to keep pace with ever-increasing performance requirements as our customers develop these beneficial products,” Schmidt says. “With AI materials design tools, our researchers can more easily leverage Dow’s long history of materials science expertise to quickly respond to new design requirements, whether that is advanced performance, improved sustainability or cost. We envision a future with data-driven tools in our labs, and I’m excited to see how this project can accelerate the AI journey.”

Ross Maciejewski, director of the School of Computing and Augmented Intelligence, agrees. “This grant is an interesting example of the type of collaboration between enterprise and academia that can really propel innovation,” he says. “Tackling the world’s big problems will require both research and manufacturing solutions.”

The Grainger Foundation Frontiers of Engineering Grants are designed to foster exactly this kind of interdisciplinary approach. The foundation gives away only two awards after each symposium that provide the seed money to drive important research forward. It’s the next lap on an already promising track for Fu, who was named an Early Career Engineer by the NAE in 2020.

Fu is looking forward to developing the new AI technology with Schmidt. He compares the process to cooking.

He says, “Thanks to these machine learning systems, we’ll be in the kitchen with only the ingredients likely to make tasty dishes.”