Breakthrough in Russia: Polytechnic University Engineers Develop Continuous Carbon Fiber Composite Production Technology

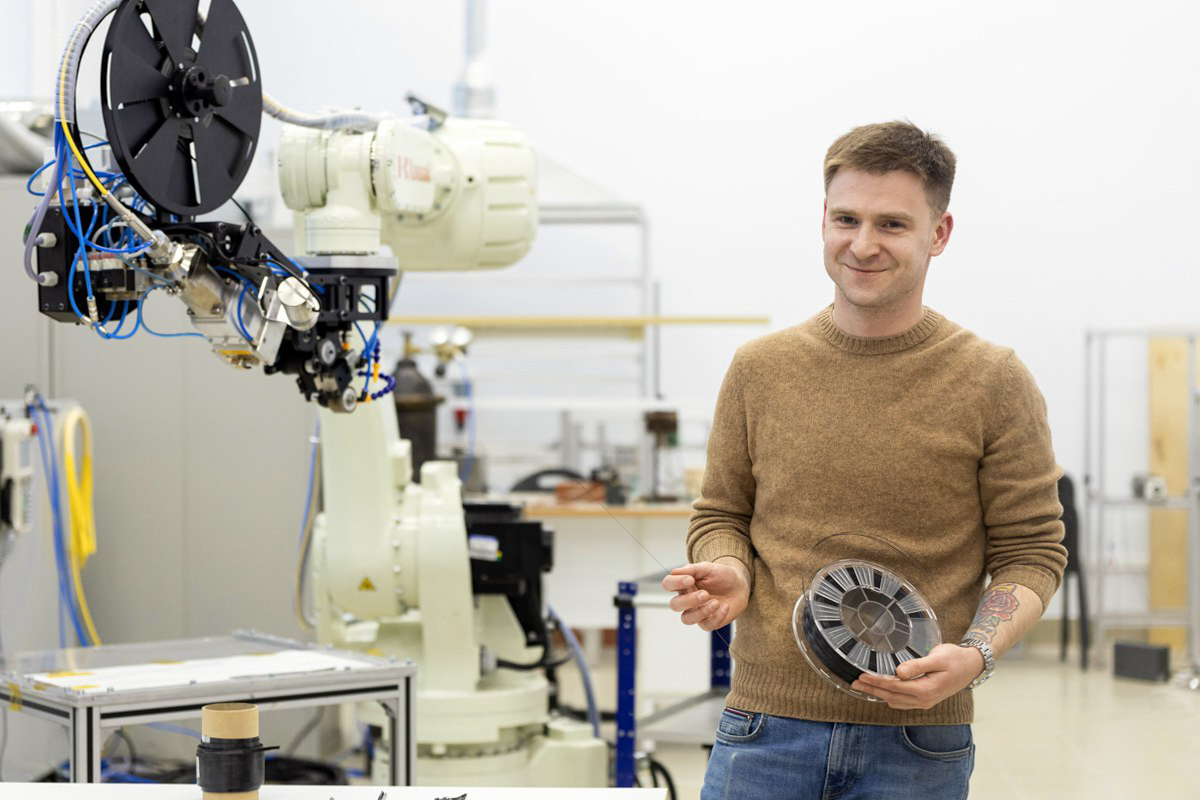

For the first time in Russia, specialists of the School of Advanced Engineering Studies in Digital Engineering of Polytechnic University have developed a pilot technology for the production of filaments (a consumable material in the form of filament used for 3D printing) made of continuous carbon fiber based on thermoplastics. Filament has unique physical and mechanical properties compared to other materials used in 3D printing and is used in the rocket and space, aviation, and engine industries.

Carbon fiber has high strength and stiffness while being very lightweight. This allows it to be used to create strong and lightweight parts that can withstand heavy loads. At the same time, carbon fiber is resistant to high temperatures or chemical attack.

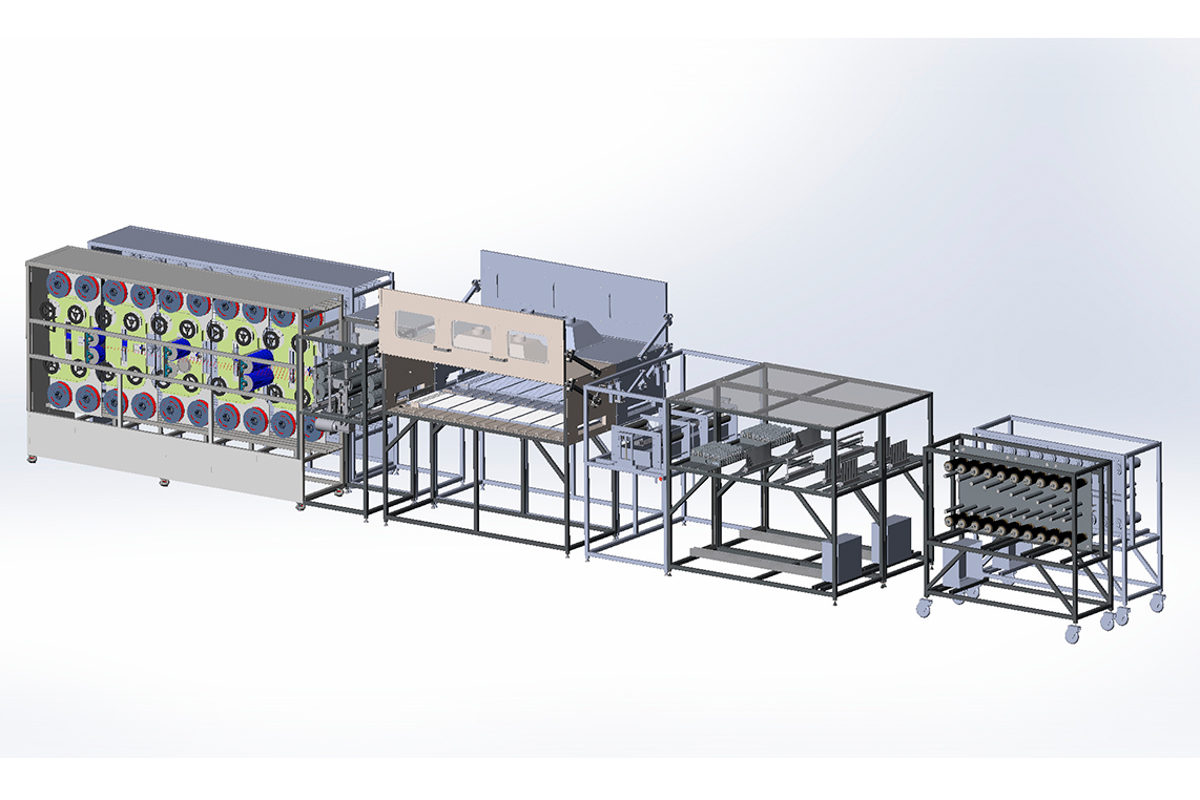

Composite materials (including filaments) from continuous carbon fiber are currently strategic and are practically not exported. Employees of SPbPU Digital Engineering have developed not only the technology for manufacturing filaments from continuous carbon fiber based on thermoplastics, but also manufactured a laboratory unit for its production with a capacity of 500 meters of filament per hour.

The production of filaments from continuous carbon fiber and high-temperature polymers is based on suspension impregnation technology.

Currently, the specialists of the School of Advanced Engineering Studies in Digital Engineering of SPbPU are developing technology and a pilot plant for filament production with a capacity of 12,000 meters per hour. In summer 2024, the pilot line will be put into operation at the production site of the Composite Division of Rosatom.