Breakthrough Nanoceramics Show Promise in Enhancing Smartphone and TV Display Technology

Scientists from the Ural Federal University, together with colleagues from India and the Ural Branch of the Russian Academy of Sciences, have developed a nanoceramic that glows in three main colors – red, green, and blue. The new material is extremely strong because it is created under high pressure. Scientists believe that the characteristics of the new nanoceramics – luminescence, strength, and transparency – will be useful for creating screens with improved brightness and detail for smartphones, televisions, and other devices. The scientists published detailed information about the new nanoceramics and their properties in the journal Applied Materials Today. The research was supported by the Russian Science Foundation (№ 23-72-01024) and the Priority 2030 program. Experimental work was carried out under the state contract (AAA-A19-119031890025-9).

“We obtained optically transparent nanoceramics capable of luminescing in red, green, and blue colors. This was made possible by adding carbon particles that act as carbon nanodots. During the synthesis process, the carbon components are encapsulated between the ceramic particles, creating defects on their surface. We believe that these defects create several energy levels in the carbon nanodots, allowing the material to glow in different colors in the visible spectrum”, explains Arseny Kiryakov, the co-author of the work, Associate Professor of the UrFU Department of Physical Techniques and Devices for Quality Control.

Carbon nanodots are small clusters of carbon atoms a few nanometers in size. Carbon nanodots are characterized by a special type of covalent bonding and an active surface. As a result, the luminescence efficiency of carbon nanodots can reach 70 percent, allowing them to be used as a light-emitting substance in the creation of displays.

“Since our nanoceramics can provide all three basic colors of the spectrum (red, green, and blue), there is no need to use three LEDs separately – it will be enough to place a single element on the light-emitting chip to produce all three colors. Also, since the synthesis of ceramics is carried out under high pressure, the nanoparticles are very close to each other – this allows for the elimination of defects, achieves optical transparency, and increases strength. Such characteristics will be useful for the production of smartphone and tablet displays because the increased concentration of carbon nanodots will increase the efficiency of luminescence, which can contribute to the growth of pixel density in the display per unit area”, explains Yulia Kuznetsova, the co-author of the work, Associate Professor of the UrFU Department of Physical Techniques and Devices for Quality Control.

Pixels are the smallest elements of color reproduction on a display. The combined luminescence of the pixels allows the image to be displayed on the screen, and the color gamut is formed by the combination of red, green, and blue.

“For a good picture, the number of pixels and the efficiency of their luminescence are particularly important. Displays that concentrate a lot of pixels have a sharper image, but the brightness suffers. Conversely, displays with fewer pixels have poor picture quality but good brightness. The ceramic we have developed differs from traditional phosphors in the type of luminescence centers. This allows us to increase the number of pixels on the screen while maintaining the brightness level”, explains Yulia Kuznetsova.

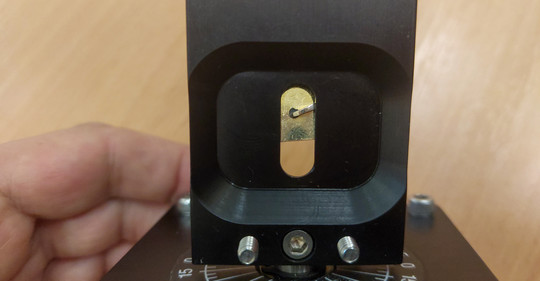

The material used to create the nanoceramics was alumina-magnesium spinel, a material with a cubic crystal lattice structure. This ensures that light passing through the material is not refracted or scattered. The ceramics were synthesized by thermobaric compression, a process in which the material is subjected to enormous pressure at a relatively low temperature.

“Thermobaric compression is a process of applying high pressure in the order of several gigapascals – such pressure is realized in the Earth’s crust at a depth of 50-60 kilometers. The high pressure allows us to reduce the synthesis temperature to values of 500-600 °C – this is twice as low as similar methods for the synthesis of nanoceramics, such as uniaxial hot pressing or spark plasma sintering. This combination of pressure and temperature allows us to get rid of various macro defects, such as cracks, pores, and large crystallites because nanoparticles in the process of synthesis undergo a kind of plastic deformation due to the fact that they begin to shift relative to each other, rotate and fill all possible voids”, says Arseny Kiryakov.

The study involved researchers from the Saveetha University (India), the Department of Physics of the Thiagrajar College of Engineering (India), and the Institute of Solid State Chemistry, Ural Branch, Russian Academy of Sciences.