Commercialization fellows working on market-ready tech

Cornell Engineering’s newest cohort of seven Ph.D. Commercialization Fellows will spend this summer and fall developing their technologies – needle-free vaccine delivery, wireless vehicle charging and a DIY robot, to name a few – and getting them ready for market.

Now in its fifth year, the commercialization fellowship program helps engineering doctoral students explore the market potential for their research. Each student will spend a fully funded summer and semester learning about intellectual property, marketing, product development, fundraising and other areas from entrepreneurship experts in industry and academia.

The fellows work one-on-one with mentors to identify potential market opportunities and develop a strategic business plan for scaling up their technology. In the second half of the program, fellows will be matched with teams of MBA students who will assist in finalizing business plans and developing potential investor pitch materials.

The 2020 fellows and their technologies are:

- Hedan (Lillia) Bai ’16, M.S. ’19, stretchable lightguides for multimodal sensing: A highly stretchable fiber-optic sensor that can simultaneously measure mechanical deformations such as stretching; bending; pressing; detecting location; and magnitude. The lightguides can provide sensing functions for a number of potential applications, including sensing for human tissue, clothes and robotics, and have been implemented as a wireless VR glove.

- Houston Claure, resource allocation with fairness constraints: An algorithm developed for deployment in team settings where resources – such as time, attention and tools – need to be distributed by an individual or robot. The algorithm assists in making such decisions by learning about each team member’s skill level while taking the notion of fairness into consideration. It has potential applications for teachers and coaches.

- Yehou Gnopo, M.S. ’18, mucosally delivered vaccine system: A multiantigen vaccine delivery system that induces mucosal immunity by a simple swab of the cheek with a cotton swab. The system consists of bacterial outer membrane vesicles that are engineered to induce a strong immune response at mucosal surfaces such as the mouth, nose and lungs, which are primary sites of pathogen infection.

- Meishen Liu, wastewater ion separation using carbon dioxide: A method of capturing carbon dioxide from the air using sodium glycinate, then using the resulting solution to separate valuable elements – such as soluble carbonates of lithium, calcium and magnesium – from industrial wastewater streams, rendering the method cash positive and carbon negative.

- Brandon Regensburger, M.S. ’19, wireless charging for electric vehicles: A capacitive wireless power transfer system suitable for in-motion charging of electric vehicles. The approach uses electric field coupling between metal plates to transfer energy, allowing the capacitive system to be much smaller, lighter, less expensive and easier to embed in the ground than traditional inductive charging systems.

- Jaejeong (Jane) Shin, real-time intelligent sensor path planning: A path-planning algorithm for autonomous air, ground and underwater vehicles that combines computer vision with information theory. The algorithm requires significantly low computational time so the optimal path can be determined in real time as the vehicle is moving and the sensors are obtaining new information about the environment.

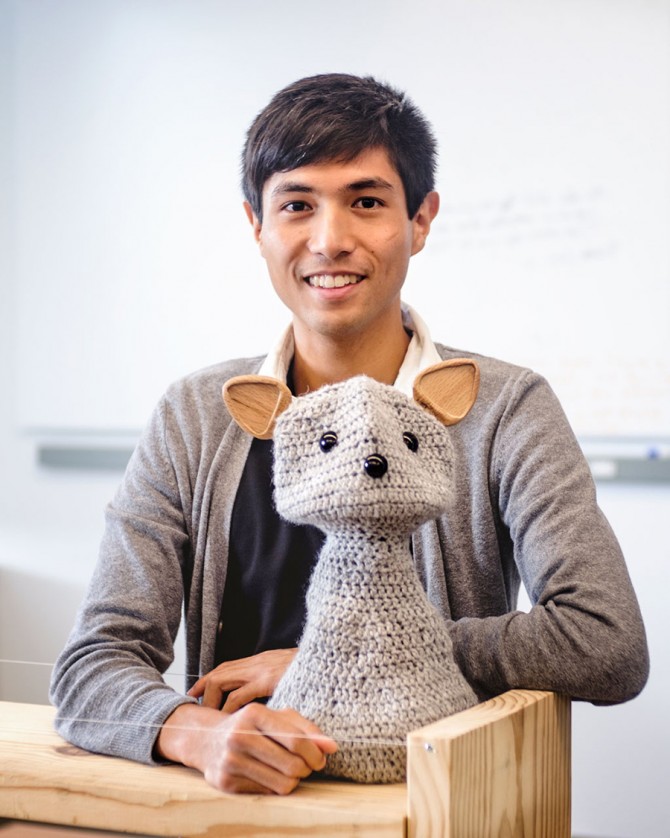

- Michael Suguitan, DIY social robot: A social robotics kit that is uniquely “nonrobotic” in that its exterior is made from soft materials and its interior is mechanically compliant. Users are directly involved in its construction and deep learning models are used to generate its behaviors. It is designed as an accessible platform for teaching the technical and creative aspects of robotics engineering to a broad audience.

This year’s cohort is one of the most diverse across technologies, engineering departments and demographic backgrounds, according to fellowship lead instructor Tom Schryver ’93, MBA ’02, executive director of the Center for Regional Economic Advancement.

“One of the things I love about the program is that since we do it as a cohort, the fellows can observe and learn from their colleagues’ experiences,” said Schryver, a visiting lecturer at the Samuel Curtis Johnson Graduate School of Management. “By having a very broad range of technology areas but similar tasks – identify market opportunities, design and test a business model – they can learn a lot from one another.”

Schryver said all program components are being administered virtually due to the COVID-19 pandemic, but the overall architecture of the program hasn’t changed.