Cutting-Edge Tech: Polymer Holds Potential for Energy-Efficient Building Solutions

University of Texas at Dallas researchers and their collaborators are developing a quick-drying polymeric desiccant that could dehumidify buildings using at least 30% less energy than conventional air-conditioning systems.

The researchers received a $1.7 million, four-year National Science Foundation grant to develop the desiccant as a more energy-efficient method to remove moisture from buildings.

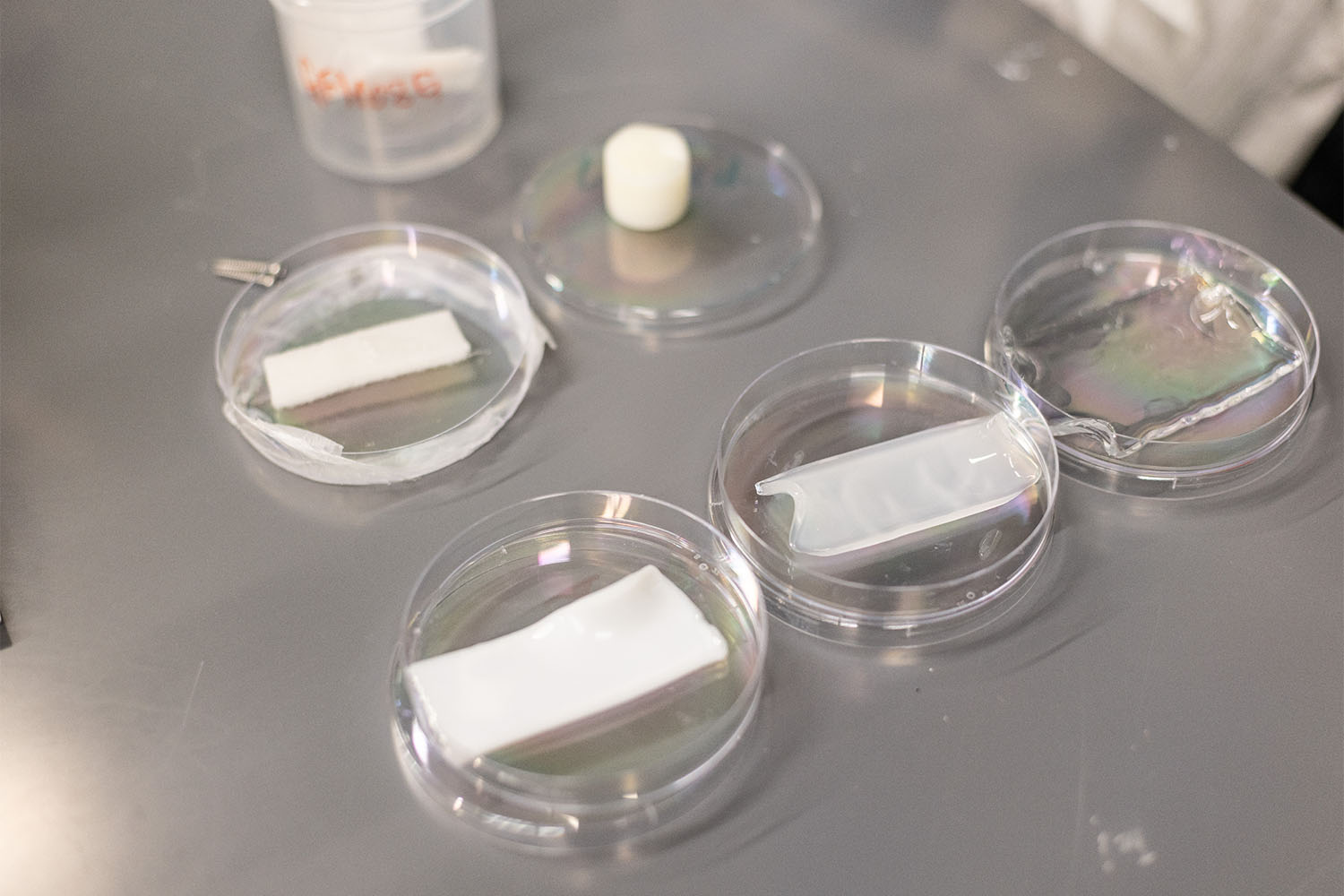

The researchers’ thermo-responsive material absorbs moisture from air and dries quickly when exposed to low heat, said Dr. Shuang (Cynthia) Cui, principal investigator and assistant professor of mechanical engineering in the Erik Jonsson School of Engineering and Computer Science.

Cui envisions that inside a building’s heating, ventilation and air-conditioning system, the desiccant would coat a rotating cylinder and absorb moisture from air during part of a rotation. Then, as the structure rotates, the water-filled material would move through a regeneration stage that exposes it to low heat to remove the absorbed moisture. The cycle would repeat continuously.

“Our goal is to develop the desiccant to help dehumidify and cool buildings more efficiently than conventional air-conditioning systems and lower carbon emissions significantly,” Cui said. “It is imperative to improve dehumidification energy efficiency. Efficient air dehumidification represents an excellent opportunity to reduce energy use and greenhouse gas emissions to facilitate the sustainability and decarbonization movement to counteract climate change.”

To learn more about how UT Dallas is enhancing lives through transformative research, explore New Dimensions: The Campaign for UT Dallas.

Air conditioners and electric fans account for 20% of the total electricity used in buildings worldwide, and demand is expected to soar, according to the International Energy Agency. Dehumidifying warm air can consume half or more of an air conditioner’s energy.

The thermo-responsive desiccant can make air conditioning more energy efficient by separating the dehumidification and heat removal processes and improving the most energy-consuming steps. For example, unlike traditional air-conditioning systems, a system using the desiccant would not need to cool coils at low temperatures to condense moisture from the air as part of the dehumidification process. Also, in contrast to a traditional air conditioner, the desiccant would likely not need to be heated to high temperatures to evaporate the collected moisture.

The project, which began in 2023, is an interdisciplinary effort. Cui is working with co-principal investigators from UT Dallas, two other academic institutions and an industry partner:

- Dr. Mihaela Stefan, Eugene McDermott Distinguished Professor and department head of chemistry and biochemistry, and professor of bioengineering and of materials science and engineering at UT Dallas.

- Brandon Wilcox, chief operating officer at OxiCool Inc., a Malvern, Pennsylvania-based air-conditioning company, which will assist with the technology transfer and commercialization.

- Dr. Zheng O’Neill, associate professor of mechanical engineering at Texas A&M University.

- Dr. Jianli Chen, assistant professor of civil and environmental engineering at The University of Utah.

Cui and researchers from the National Renewable Energy Laboratory, where Cui previously worked, published a study detailing the optimal polymer structure in the Sept. 8 print edition of Advanced Energy Materials. Researchers continue to optimize the structure to help it absorb more moisture while also drying quickly at a low energy input.

Stefan said she and researchers in her lab are developing a range of thermo-responsive polymers to determine which formulas work best. She said she is impressed with Cui’s work in applying the thermo-responsive polymer typically used in drug delivery applications to build dehumidification.

“Dr. Cui’s creativity to bring these thermo-responsive polymers into this new application is amazing,” Stefan said.

Stefan also said that Cui’s collaboration with an industry partner is key to ensuring that the research will have a real-world impact.

“Dr. Cui’s research is very application-driven,” Stefan said. “She wants to make a difference, and with her industry partnership, she will take the thermo-responsive polymer to the next level.”