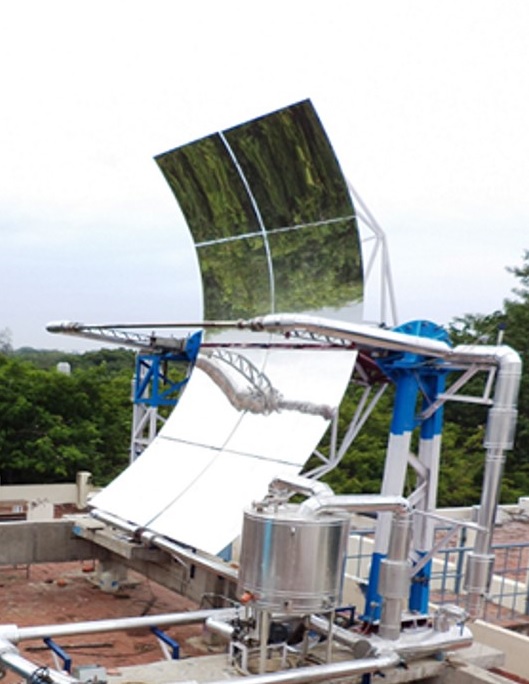

Chennai: Indian Institute of Technology Madras Researchers have developed a low-cost Solar ‘Parabolic Trough Collector’ (PTC) system for concentrating solar energy with industrial applications in areas such as desalination, space heating and space cooling, among others.

This indigenously designed and developed system is lightweight with high energy efficiency under Indian various climatic and load conditions. The system can be integrated effectively with various process heat applications. This research can help manufacturers and researchers in solar energy make devices with higher efficiency.

The National Solar Mission was launched with the target of providing 20,000 MW through solar power by 2022. However, lower rate of energy generation through solar power is a major roadblock in achieving this target. Technologies such as this one developed by IIT Madras researchers can help meet this target.

The research was led by Prof. K. Srinivas Reddy, Heat Transfer and Thermal Power Laboratory, Department of Mechanical Engineering, IIT Madras, with his team member Mr. C. Ananthsornaraj.

Speaking about the application of solar energy to meet energy needs, Prof. K. Srinivas Reddy said, “Solar Energy technology is the most propitious technology for clinching sustainability in the energy domain. Particularly, Concentrated Solar Power (CSP) technology can meet thermal and electrical energy demands due to its high dispatchability and reliability. States such as Bihar, Haryana, Madhya Pradesh, Maharashtra and Gujarat, among others, have great potential to harness this energy, which can reduce the combustion of non-renewable and polluting sources of energy such as coal and petroleum.”

The research team tested the efficiency of this installed system in terms of optical efficiency and thermal efficiency. Optical efficiency is the amount of energy which is absorbed by the tube over the total energy received by the collector. Thermal efficiency, on the other hand, is the heat collected over the heat gain by the system. They found that the optical efficiency of the evacuated system is 72 per cent and non-evacuated system is 68 per cent when the heat loss is minimised.

Elaborating about varied applications of this research in different sectors, Prof. K. Srinivas Reddy said, “We intend to commercialise this product and demonstrate the application of PTC technology with energy storage for sustainable energy solutions in agriculture, food, dairy and industrial process heat sectors.”

The researchers further found that the rate at which the heat transfer liquid flows also affected the thermal performance of the system. When the flow rate of the liquid was higher (0.12kg/second), thermal efficiency was higher (66 per cent for the evacuated system and 64 per cent for non-evacuated system) whereas at the lower flow rate (0.06 kg/second), thermal efficiency was lower (64.3 per cent for evacuated system and 62.1 per cent for non-evacuated system). Thermal efficiency also varied depending on whether it was sunny or cloudy day.

ABOUT PTC SYSTEMS

Parabolic Trough Collector (PTC) systems concentrate sunlight onto a small area where it is absorbed and then utilised for heating and subsequently for energy generation. This system consists of a concentrator/reflector, receiver, supporting structures (pylon, torque tube, mirror supporting arm and receiver support) and tracking unit. The concentrator of the parabolic trough collector system receives the solar incident radiation from the sun and reflects it onto the receiver which is placed at the focal line of the PTC system to heat a liquid.

This heated liquid boils water making steam to run turbines and generators for generating electricity. The tubes, which absorb this sunlight from reflectors, have a glass exterior and metal interior holding a heat transfer liquid, which can be molten salt and oil, among others. To minimise thermal loses, the space between glass exterior and metal interior is maintained at low-pressure conditions, called ‘evacuated receiver system.’