IIT Madras Researchers Develop Ultrasonic Waves-based Temperature Measurement Sensors for Industrial Furnaces

Chennai: Indian Institute of Technology Madras Researchers have developed a disruptive sensor technology to greatly increase the efficiency of industrial ovens in fertilizer, petrochemical, chemical and manufacturing sectors.

Called ‘μTMapS’ (or) ‘Multi Point Temperature Measurement Sensor,’ it provides automated and intelligent measurements that can replace existing heat process control systems that cause expensive forced shutdowns and early retirement of components well before its designed life.

High-temperature processes are critical to oil and gas, chemical, power generation and manufacturing industries. However, the control of these process has been a challenge due to the complexity in the processes. Currently, industries use sparse measurements and the data are interpreted through manual intervention and/or operator intuitions.

IIT Madras Researchers at the Centre for Non-destructive Evaluation developed an Ultrasonic Waves-based temperature Measurement Sensors that can accurately measure temperatures in the range of -100°C to 1,400°C. This technology also generates data in real-time through Industrial Internet of Technology (IoT) devices, which will provide inputs to the industry to greatly improve their manufacturing processes and enhance their process efficiency.

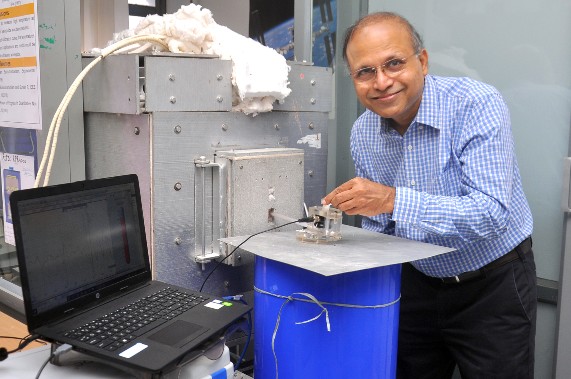

Elaborating on this technology, Prof. Krishnan Balasubramaniam, Institute Professor, and Head, Centre for Non-destructive Evaluation, IIT Madras, said, “Any industry that uses a lot of heat to process materials such as metals or polymers has to ensure that the entire furnace has a uniform temperature across the board. This is critical to reducing defective products. However, existing technologies for this purpose have a lot of gaps and our Research Team at Centre for Non-destructive Evaluation set out to address these gaps.”

Further, Prof. Krishnan Balasubramaniam said, “We have licensed our technology to an IIT Madras-incubated start-up called ‘Xyma Analytics,’ which has been field testing the technology for the past one year in Indian industries to establish its reliability, performance and benefits. We plan to commercially introduce this technology for Indian and foreign manufacturing industries within the next one year.”

The data generated by these sensors can be processed through Artificial Intelligence and Machine Learning to develop better designs for ovens and furnaces that can greatly reduce the cost and enhance efficiency for industries. The Researchers have already been granted patents for this technology in India and the U.S.

Speaking about the market potential for ‘μTMapS,’ Dr. Nishanth Raja, Chief Executive Officer, XYMA Analytics, said, “We are looking at Indian and foreign markets, targeting industries that need industrial ovens at temperatures above 50°C. Our targets are refineries, fertilizer, petrochemical, chemical and manufacturing industries such as metal, steel, aluminium, glass, polymer and copper. The semiconductor industry is also of great interest to us as temperature control is important for this industry too.”

IIT Madras Researchers have been working on this technology for more than two decades and many Intellectual Property (IPs) have come out already with several more in the pipeline. This technology utilizes ultrasonic waves in the frequency of 100 kHz to 300 kHz, which humans cannot hear.

The researchers use a wire embedded with sensor markings and install them in furnaces. As the ultrasonic wave travels through this wire, the sensor markings will measure the time and the feedback to calculate the temperature at different points of the furnace. A single wire can be more than 100 metres long and can cover an entire industrial furnace, with little footprint. Many industries now use several thermo-couples for this purpose. However, their range is limited and using a lot of thermo-couples results in a higher footprint that can negatively impact the process.

The Industrial IoT technology reads the data detected by the sensors and transmits them in real-time. The air patterns in the furnace can be changed in real-time to make the heating more uniform. The history of the thermodynamics of these components can be used to figure out when the failure of a component can happen.