KIT and Audi are working on recycling methods for automotive plastics

Numerous components in cars are made of plastics. They have high requirements for safety, heat resistance and quality. Plastic components in cars that are subject to particularly intense stress can therefore only be manufactured from petroleum-based materials. Most of these cannot be recycled. While single-type plastics can often be mechanically recycled, recycling mixed plastic waste is a major challenge. The THINKTANK Industrial Resource Strategies at the Karlsruhe Institute of Technology (KIT) is therefore starting a pilot project for chemical recycling with Audi in order to return these mixed plastic fractions to a resource-saving cycle.

“To date, it has not been possible to recycle automotive plastics for many components, which is why we are doing pioneering work here with Audi,” says Professor Dieter Stapf, head of the Institute for Technical Chemistry at KIT and involved in THINKTANK. “If we want to close the loop, then we have to develop suitable processes for this.” Chemical recycling is so far the only method with which it is possible to convert such mixed plastic waste back into products of new quality. This enables a wider range of plastics to be recovered, says Stapf. “Such closed material cycles save valuable resources because less primary material is required. This in turn saves energy and costs – and is good for the environment, ”says Dr.

The pilot project “Chemical recycling of plastics from automobile construction” is being carried out by the THINKTANK Industrial Resource Strategies, which the Baden-Württemberg state government set up at KIT together with industry and with the support of science. “The responsible use of raw materials is the shared responsibility of business, science and politics. In THINKTANK we bundle all competencies in order to face this great challenge in the service of society and the environment ”, says Professor Thomas Hirth, Vice President of KIT for Innovation and International Affairs and spokesman for THINKTANK.

“Chemical recycling can be a very important building block for comprehensive plastics recycling. That is what makes it so interesting for the automotive industry. The THINKTANK and Audi are jointly tackling a central topic of making automobiles more sustainable and environmentally friendly in the future, regardless of the drive. The holistic view of raw material cycles is the focus of the THINKTANKS ”, says the managing director of the THINKTANKS, Dr. Christian Kuehne.

Audi is one of the first automobile manufacturers to test this recycling method in a pilot project with plastics from automobile production. “We want to establish intelligent cycles in our supply chains and use resources efficiently,” says Marco Philippi, Head of Procurement Strategy at Audi. “Chemical recycling has great potential for this: If plastic components can be manufactured from pyrolysis oil instead of crude oil without any loss of quality, it would be possible to significantly increase the proportion of sustainably manufactured parts in the car. In the long term, this process can also play a role in end-of-life vehicle recycling. “

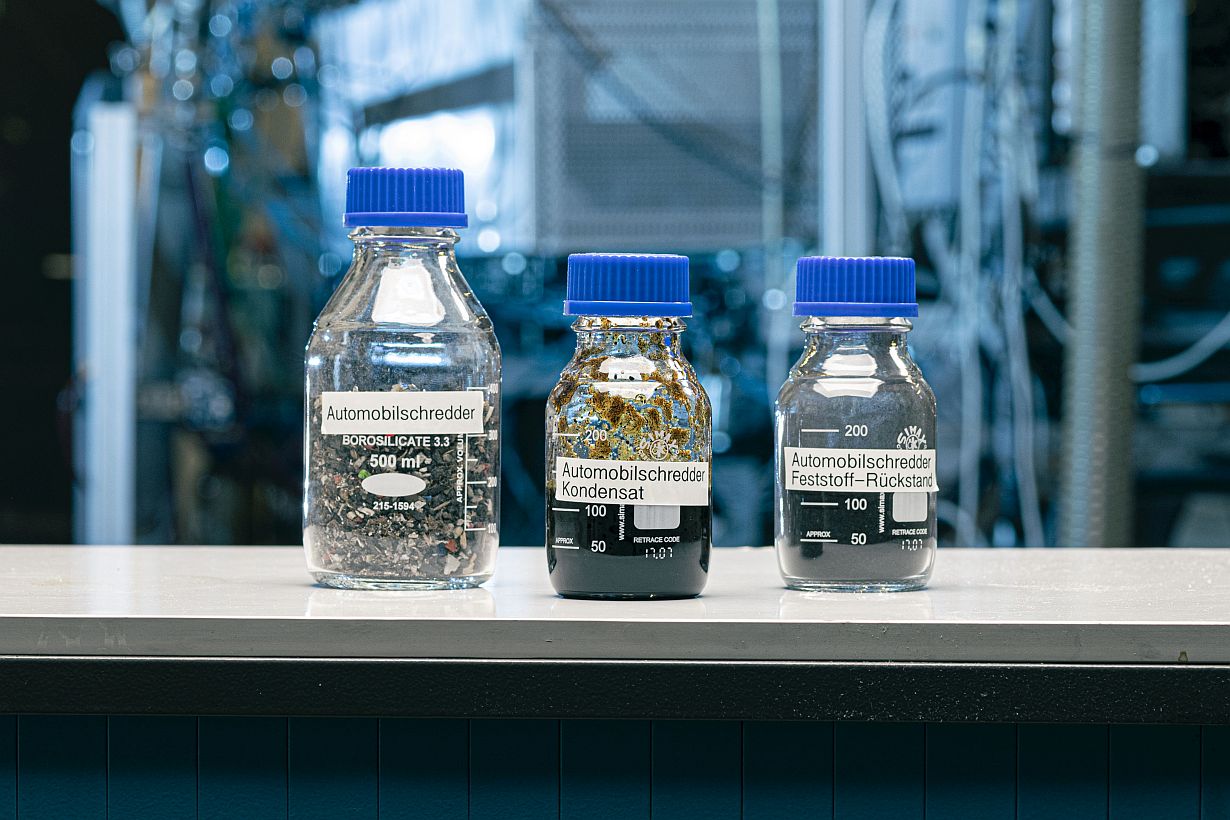

The pilot project “Chemical recycling of plastics from automotive engineering” aims to create intelligent cycles for plastics and to establish this method as a supplement to mechanical recycling and instead of energy recovery. With the THINKTANK at KIT as a partner, Audi initially wants to test the technical feasibility of chemical recycling and evaluate the process for economic efficiency and environmental impact. For this purpose, the company provides plastic components that are no longer required, such as fuel tanks, wheel covers or radiator grilles from Audi models, which, for example, are returning from the German dealer network. These plastic components are processed into pyrolysis oil through chemical recycling. In the medium term, components made from pyrolysis oil can be reused in automobiles. Succeeds,

Pyrolysis process for more sustainable products

Research and technology development for a sustainable circular economy are a core topic at KIT. “We are systematically investigating what can be achieved with pyrolysis and how pyrolysis processes must be designed on a large scale so that waste can be recycled as raw materials as possible,” says Stapf. The chemical recycling of plastic waste could make modern products more sustainable and avoid greenhouse gas emissions.