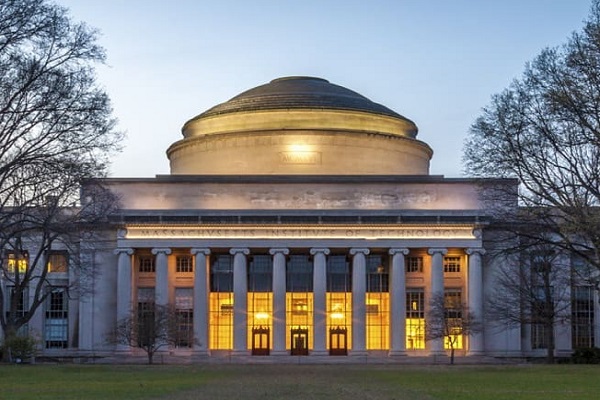

Massachusetts Institute of Technology: MIT.nano adds new instruments to create and analyze at the nanoscale

MIT.nano has added several instruments to its tool set, expanding the facilities’ capabilities at the nanoscale. The tools, located in MIT.nano’s cleanroom and characterization spaces, can be used individually, or they might all be utilized during different stages of one complete project.

“Overall, these tools are important additions to MIT.nano that will help researchers create and analyze at the nanoscale,” says Jorg Scholvin, assistant director for Fab.nano. “Each fills a critical gap in our existing set of capabilities. What’s really exciting is the range — they can all handle the smallest pieces up to 200-millimeter wafers.”

The Arradiance GEMStar XT-DP plasma-enhanced atomic layer deposition (ALD) system was installed at MIT.nano in May. The system is dedicated specifically to deposit high-quality nanometer-scale thin oxide films including aluminum oxide, hafnium oxide, zirconium dioxide, and silicon dioxide. The Arradiance ALD can be used for samples ranging from small pieces up to 200-mm wafers and has a load lock that isolates the deposition chamber from the user, allowing for better contamination control.

The Elionix HS50 is a high-speed electron-beam lithography tool added to one of the high-performance imaging suites on the first floor of MIT.nano’s cleanroom. It enables high-resolution patterning of feature sizes down to 20 nanometers. Like the Arradiance, the system can process samples from small pieces up to 200-mm wafers. It has an integrated load lock that lets a user load multiple samples and write patterns overnight. The HS50 can also function as a high-capacity scanning-electron microscope, allowing researchers to inspect and analyze the exposed e-beam patterns with high efficiency.

Pairing well with the HS50 is MIT.nano’s new Temescal FC-2800 e-beam evaporator, installed in August in MIT.nano’s first-floor cleanroom. This tool can accommodate up to eight different source materials with an isolation valve that separates the sources from the sample chamber. This allows for faster pump down, while also affording users the opportunity to change sources without breaking vacuum to their samples. This new evaporator has a large cryo pump to achieve low base pressures quickly, and it has a long throw distance of 42 inches. The low pressure and long path combine to provide a more uniform deposition, which is critical to enabling liftoff of nanoscale features patterned on the HS50. The Temescal can also handle small pieces up to six 200-mm wafers.

To complement its nanofabrication capabilities, MIT.nano has also added two instruments for nanoscale imaging and analysis — the Hitachi Regulus 8100 scanning-electron microscope (SEM) and the Hitachi HF5000 environmental transmission electron microscope (ETEM). The Regulus, located in MIT.nano’s third-floor cleanroom, can feature resolutions as small as 0.8 nanometers at low-accelerating voltages and is equipped with an energy dispersive spectroscopy (EDS) detector, adding correlative imaging and elemental analysis capability to the cleanroom setting.

The HF5000, a long-term loaner instrument from Hitachi positioned in MIT.nano’s basement-level characterization facility, can achieve spatial resolution down to 0.078 nanometers. It is easy to use and allows for simultaneous SEM /STEM/ EDS correlative imaging and analysis in a single configuration.

“The unique strength of the HF5000 STEM is its capability for real-time imaging of dynamic processes under oxygen/hydrogen or humid atmospheres and heating or electrical biasing. This can provide mechanistic insights on the materials growth and degradation, oxygen exchange reactions, defects formation, hydrogen embrittlement, and electronic device operation,” says Anna Osherov, assistant director for Characterization.nano. “This microscope introduces exciting new imaging possibilities to our users.”

Together, these tools make up just a portion of the new capabilities at MIT.nano. The open-access facility, available to any trained MIT researcher, as well as external users from academia and industry, now has more than 160 tools and instruments installed. Over the past six months, additional domain experts have joined MIT.nano’s technical staff to assist researchers with training and use of these tools.