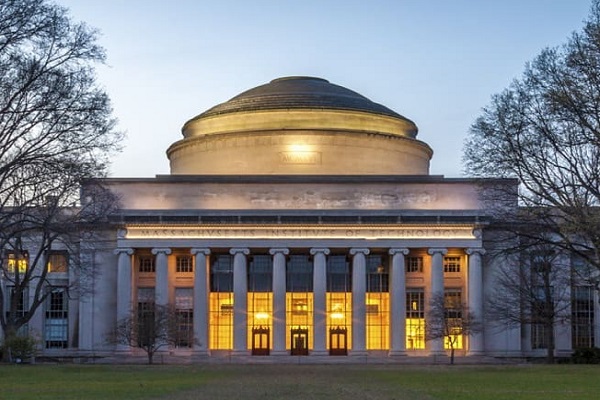

Massachusetts Institute of Technology: Study examines how machine learning boosts manufacturing

Which companies deploy machine intelligence (MI) and data analytics successfully for manufacturing and operations? Why are those leading adopters so far ahead — and what can others learn from them?

MIT Machine Intelligence for Manufacturing and Operations (MIMO) and McKinsey and Company have the answer, revealed in a first-of-its-kind Harvard Business Review article. The piece chronicles how MIMO and McKinsey partnered for a sweeping 100-company survey to explain how high-performing companies successfully wield machine learning technologies (and where others could improve).

Created by the MIT Leaders for Global Operations (LGO) program, MIMO is a research and educational program designed to boost industrial competitiveness by accelerating machine intelligence’s deployment and understanding. The goal is to “find the shortest path from data to impact,” says managing director Bruce Lawler SM ’92.

As such, the McKinsey project encapsulates MIMO’s mission of demystifying effective machine-learning use. The survey studied companies across sectors, probing their digital, data analytics, and MI tech usage; goals (ranging from efficiency to customer experience to environmental impact); and tracking. Respondents were drawn from MIT and McKinsey’s wide-ranging networks.

“The study is probably the broadest that anybody has done in the space: 100 companies and 21 performance indicators,” says Vijay D’Silva SM ’92, a senior partner at McKinsey and Company who collaborated with MIMO on the project.

Overall, those who extracted the biggest gains from digital technologies had strong governance, deployment, partnerships, MI-trained employees, and data availability. They also spent up to 60 percent more on machine learning than their competitors.

One standout company is biopharmaceutical giant Amgen, which uses deep-learning image-augmentation to maximize efficiency of visual inspection systems. This technique pays off by increasing particle detection by 70 percent and reduces the need for manual inspections. AJ Tan PhD ’19, MBA ’21, SM ’21 was instrumental in the effort: He wrote his LGO thesis about the project, winning last year’s Best Thesis Award at graduation.

Lawler says Tan’s work exemplifies MIMO’s mission of bridging the gap between machine learning and manufacturing before it’s too late.

“We saw a need to bring these powerful new technologies into manufacturing more quickly. In the next 20 to 30 years, we’re going to add another 3 billion people to the globe, and they’re going to want the lifestyles that you and I enjoy. Those typically require manufactured things. How do we get better at translating natural resources into human well-being? One of the big vehicles for doing that is manufacturing, and one of the newest tools is AI and machine learning,” he says.

For the survey, MIMO issued each company a 30-page playbook analyzing how they compared against other companies across a range of categories and metrics, from strategy to governance to data execution. This will help them to target areas of opportunity or where to invest. Lawler hopes that this will be a longitudinal study with a wider scope and playbook each year — a vast but impactful undertaking with LGO brainpower as the driving engine.

“MIT was hugely important and critical to the piece of work and an amazing partner for us. We had talented MIT students on the team who did most of the analysis jointly with McKinsey, which improved the quality of the work as a result,” says D’Silva.

This collaborative approach is central to MIMO’s philosophy as an information convener and partner for the private sector. The goal is drive “an effective transformation in industries that achieve not just technical goals, but also business goals and social goals,” says Duane Boning, engineering faculty director at MIT LGO, and faculty lead at MIMO.

This fusion of research and collaboration is the logical next step for LGO, he says, because it’s always been at the forefront of problem-solving for global operations. Machine learning is definitely the latest big knowledge gap for many businesses, but not the first, and MIMO can teach companies how to apply it.

“[I liken] it to 30 years ago when LGO got started, when it was all about lean manufacturing principles. About 15 years ago, it was the supply chain idea. That sparked us to think — not just for our LGO students, but for the benefit of industry more broadly — for understanding this big change, for facilitating it, for doing research and getting connections into other actual research activities, we need some effort to catalyze this,” Boning says. “That’s [MIMO’s] real excitement: What are ideas that work? What are methodologies that work? What are technologies that work? And LGO students, in some sense, are the perfect vehicle to discover some of that.”