New technology can autonomously repair & restore high-value components such as moulds, turbine blades & aerospace components

An Indian Scientist has developed a completely autonomous technology for the repair and restoration of high-value components such as moulds, turbine blades, and other aerospace components that require minimal human intervention. It is expected that this technology will leap-frog the restoration and repair industry to the next level and help in nucleation of a viable cutting-edge laser manufacturing ecosystem for Atmanirbhar Bharat.

The existing repair techniques like welding and thermal spraying are ad hoc and do not provide accuracy and precision. Moreover, all the existing technologies are manual, and the quality of repair depends upon the skill set of the person.

Prof. Ramesh Kumar Singh, Professor, Mechanical Engineering Department, IIT Bombay, has developed a novel technology that uses a laser for excellent process control and is completely autonomous with minimal to zero human intervention. This ensures restoration with enhanced quality and repeatability.

The technology developed with support from the Advanced Manufacturing Technologies Program of the Department of Science & Technology, Government of India, has undergone validation and testing.

With the help of the technology, the defective component which requires repair will be scanned autonomously for damage detection via a laser scanner, and the deposition path will be determined based on certain algorithms. The laser-directed energy deposition (LDED) technique will be used to deposit the material, followed by finishing and automated inspection of the restored product.

The developed system consists of a robotic restoration system and is designed to function autonomously for all key activities, namely, scanning path planning, damage detection, deposition, finishing, and inspection. In addition, the process parameters will be obtained from physics-based models to induce favourable residual stress, which is one of the key limitations in restoration via additive manufacturing. This paves the way for the development of ‘science enabled technology’ solutions, which according to Prof. Ramesh Kumar Singh, are not available for restoration of high-value components.

The final integration of the two systems– the laser-directed energy deposition and the defect scanning systems, is underway, and the project is at 7th stage of the Technology Readiness Level. Prof. Ramesh has allied with Bharat Forge, Aditya Birla Science and Technology Company and Interface Design Associates for its industrial uptake.

“The developed technology is very impactful, and a game-changer for the restoration and repair segment of the manufacturing industry and has huge market potential. The components which can be reconditioned via this technology are very high-value. The level of accuracy and precision, which is possible through this technology, is phenomenal and is far ahead of the current state-of-the-art methods,” mentioned Prof. Ramesh.

According to Prof. Ramesh, it is expected that the pay-off from the technology would include the entire machine cost with around repair of twenty-odd components.

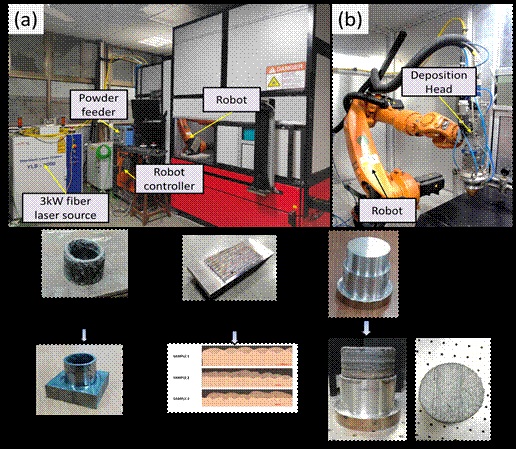

Figure1: This figure shows the complete developed system with its all subsystems. There are two options for the manipulation of the deposition head: one with 6 Axis robotic manipulators and the second with gantry-based 5 Axis systems. A 3D printed hollow cylinder, plate, and punch of H13 tool steel hard-faced with CPM 9V steel are also shown

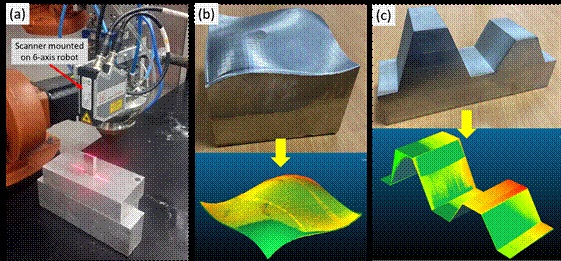

Figure2: This shows the scanning system for the damage assessment of components. The 3-D point cloud can be acquired by data-fusion of 2-D profiles obtained continuously from laser scanners and the position of robot end-effecter. The actual and scanned 3D free form components are also shown.

For more details, Prof. Ramesh Kumar Singh (+91 99309 50219, [email protected] or [email protected]) can be contacted.