New technology can help fabricate cost-effective & efficient piezoelectric devices for wearable applications

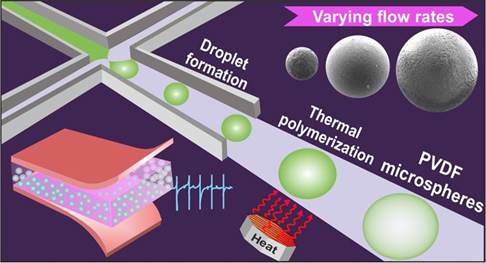

Researchers have found a droplet microfluidics technology to produce microspheres with high electroactive (EA) phase that can lead to piezoelectric devices for wearable applications, serving as self-powered sensors for monitoring diverse physiological signals.

Polymer microspheres, notable for their increased surface area and enhanced interface capabilities, have attracted substantial interest. However, existing methods for their production possess drawbacks such as shape irregularities and high energy requirements. To address these limitations, microfluidic techniques have emerged, offering benefits like tunability, size and shape control, efficiency and so on. Over the past years, microspheres of PVDF have been produced via microfluidics but the presence of high EA phase in them remains a challenge.

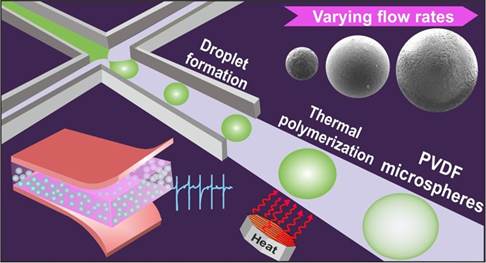

Researchers from Institute of Nano Science and Technology (INST), Mohali, an autonomous institute of Department of Science and Technology have introduced droplet microfluidics technology, combined with off-chip thermal polymerization technique to synthesize tunable Polyvinylidene fluoride (PVDF) microspheres to engineer high EA phase. The obtained microspheres exhibited uniformity and monodispersity with a narrow size distribution.

The high EA phase of microspheres was engineered through flow rates of oil and polymer solution in the microfluidic device and extensive characterization was carried out to verify the piezoelectric response of the microspheres.

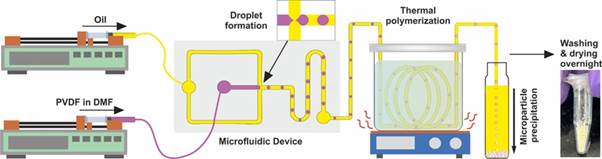

The team brought about uniformity and size control (126-754 µm) of the microspheres. By adjusting flow rates and optimizing reaction temperature, the EA phase was enhanced to around 82%. Additionally, artificial intelligence (AI) was used as a vital tool in enabling accurate predictions for microsphere diameter and phases, reducing the need for extensive laboratory optimization prior to droplet generation in microfluidics. This work was recently published in the Chemical Engineering Journal, Elsevier.

As a proof of concept, the researchers explored the application of PVDF microspheres in the development of a flexible piezoelectric device that can seamlessly integrate with different parts of human body like elbow, knee, etc., through wearables. It underwent varying degrees of compression at different rates, depending on specific body movement, harnessing the energy generated by body movements that would otherwise go waste. This generated electrical response proved to be substantial, providing enough output voltage (around 23V) to operate low-power devices.

Integration of this technology into wearables opens new pathways for efficient energy harvesting from human motion, paving the way for sustainable and self-sufficient wearable devices. The method offers numerous advantages, including simplicity, cost-effectiveness, high efficiency and control, making it highly significant for applications in biomedical sector, self-powered devices, and beyond. The research highlights the collaborative potential of microfluidics, polymer science, and AI, propelling the development of intelligent materials.

Figure: Schematic of overall work executed and its application

Figure: Schematic of the processing scheme of PVDF microparticles in a microfluidic device using off-chip thermal polymerization technique.

Figure: Digital images illustrating (a) a microreactor infused with dye to enhance visibility of microchannels and (b) PVDF microparticles