POSTECH and Hansol Chemical Join Forces to Develop Eco-Friendly Non-Fluorinated Battery Technology

A research team led by Professor Soojin Park and Seoha Nam from the Department of Chemistry at POSTECH, in partnership with Hansol Chemical’s Battery materials R&D center, has developed a new fluorine-free binder and electrolyte designed to advance eco-friendly, high-performance battery technology. Their findings were recently published in “Chemical Engineering Journal”, an international journal in the field of chemistry.

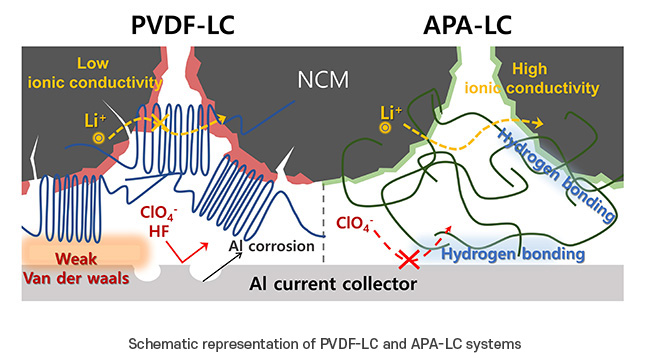

As environmental concerns intensify, the importance of sustainable materials in battery technology is growing. Traditional lithium batteries rely on fluorinated compounds such as polyvinylidene fluoride (PVDF) binders*1 and lithium hexafluorophosphate (LiPF6, LP) salts. However, this “PVDF-LP” system releases highly toxic hydrogen fluoride (HF), which reduces battery performance and lifespan. Furthermore, PVDF is non-biodegradable, and with the European Union (EU) tightening regulations on PFAS*2, a ban on these substances is expected by 2026.

Researchers from POSTECH and Hansol Chemical have designed a non-fluorinated battery system to comply with upcoming environmental regulations and enhance battery performance. They created a lithium perchlorate (LiClO4, LC)-based electrolyte to replace fluorinated LP electrolytes along with a non-fluorinated aromatic polyamide (APA) binder using Hansol Chemical’s proprietary technology. This innovative “APA-LC” system is entirely free of fluorinated compounds.

The “APA binder” reinforces the bonding between the cathode’s active material and the aluminum current collector, preventing electrode corrosion in the electrolyte and significantly extending battery life. Additionally, the “LC system,” enriched with lithium chloride (LiCl) and lithium oxide (Li2O), lowers the energy barrier at the interface to promote ion migration, leading to faster lithium diffusion and superior output performance compared to the existing LP system. Overall, the APA-LC system exhibited greater oxidation stability than the conventional PVDF-LP system and maintained 20% higher capacity retention after 200 cycles at a rapid charge/discharge rate of 1 C, within the 2.8–4.3 V range in a coin cell test.

The research team applied the APA-LC system to produce a high-capacity 1.5 Ah (ampere-hour) pouch cell. The cell maintained excellent discharge capacity and demonstrated strong performance during fast-charging trials. This marks the world’s first successful demonstration of a battery system that is entirely scalable and practical, made entirely from non-fluorinated materials, without any fluorinated compounds.

Professor Soojin Park of POSTECH expressed the significance of the research by saying, “We haven’t just replaced fluorinated systems; we’ve proven high-capacity retention and outstanding stability.” He continued, “Our solution will advance the sustainability of the battery industry, facilitating the shift to non-fluorinated battery systems while ensuring environmental compliance.”

Managing Director Young-Ho Yoon of Hansol Chemical’s Secondary Battery Materials Business remarked, “By addressing PFAS regulatory concerns, we’ve secured a foothold in the global cathode binder market, projected to reach KRW 1.7 trillion by 2026.” He added, “Continued research will solidify our position as a leading supplier of eco-friendly secondary battery materials.”