Researchers develop bi-metallic joining process to create a composite from copper and steel for engineering applications which need high thermal & electrical conductivity

Researchers have developed a novel bi-metallic joining process to create a bimetallic composite made from copper and steel, which has high thermal and electrical conductivity for engineering applications, such as heat exchangers, hydraulic pump components, cooling staves, guide plates, and hot-work tooling applications.

In the world of technological advancements, high-performing and multifunctional structures and components are in great demand. To cater to this demand, the development of bimetallic structures has gained significant attention. These structures offer a unique combination of individual material properties, making them highly customizable for a range of applications. Research in this area has significant implications for various engineering applications where the thermal conductivity and strength of the components play a critical role.

One such bimetallic composite, made from copper and steel, has high thermal and electrical conductivity, exceptional corrosion resistance, and mechanical properties.

However, welding copper and steel together can be challenging due to the differences in their melting points, thermal conductivity, and thermal expansion properties. This has made it difficult to join copper and stainless-steel bimetallic structures without defects.

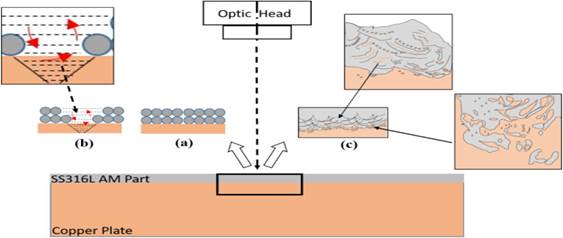

To address this challenge, researchers at the International Advanced Research Centre for Powder Metallurgy and New Materials (ARCI), an autonomous R&D Centre of the Department of Science and Technology (DST), Govt. of India, have developed a novel bi-metallic joining process using a technique called laser powder bed fusion (L-PBF) or selective laser melting (SLM) technique of metal 3D printing. This technique involves layer deposition by metal powder melting, which creates a small melt pool of stainless-steel powder with subsequent high cooling rates, limiting the intermixing of the stainless-steel melt on copper surface.

The laser beam interaction with metal during the L-PBF process creates an impact on the degree of intermixing of both copper and steel. The researchers have successfully demonstrated the formation of the interfacial microstructure and bonding mechanism and investigated the reason for achieving a strong interfacial bond.

Tensile behavior studies were conducted, which convinced the researchers of the strong copper-steel bimetallic bond at the interface. The micrographs obtained through high magnification imaging facility showed the limited intermixing of the copper and steel-rich regions across the interface. The diffusion of Fe, Cr, and Ni elements from the steel to the copper side led to solid solution strengthening of copper near the interface, with a gradient drop in hardness from the interface on the copper alloy side.

The bi-metallic joining process between stainless steel and copper alloy, using laser powder bed fusion (L-PBF) technique, has the potential to revolutionize the engineering industry by offering customizable and strong bimetallic structures with enhanced properties.