Rice Engineering Students Develop Device to Enhance Safety of Intubation for Young Babies

TinyTrach, a team of interdisciplinary engineering students from Rice University, created an innovative pediatric endotracheal tube (ETT) integrated with a camera and anchoring system that could make intubation procedures safer for babies 1 month and older by ensuring precise placement, stable anchoring and visibility access for up to 14 days.

The challenge was introduced to the team by Dr. Parag Jain, associate professor in pediatrics critical care at Texas Children’s Hospital and Baylor College of Medicine, who served as TinyTrach’s clinical advisor and one of its mentors.

“Intubation is a critical procedure for children undergoing surgery and critically ill patients, providing vital respiratory support while under sedation,” Jain said. “However, existing solutions lack a complete video-assisted intubation for pediatric-sized ETTs, which often results in significant morbidity and sometimes mortality.”

The TinyTrach team of Abi Parthasarathy, Mina Ghayour, Rian Philip, Shreya Majeti, Leighton Less, Jack Pearce and Sambhu Balakrishnan has addressed this gap with its capstone design project. The project will compete in the annual Harrell and Carolyn Huff engineering design showcase and competition, which will take place 4:30-7 p.m. April 11 at the Ion.

“The current standard of care for securing an ETT is tape, but the issue with tape is that fluid secretions from the nose and mouth can make the tape loosen, so the tube could get dislodged,” said Majeti, who added that she came to Rice knowing she wanted to be a doctor and was drawn by the opportunity to be near the Texas Medical Center.

The team went through multiple iterations of the prototype to arrive at the current design. The team members settled on a bevel-shaped piece for the anchoring mechanism, adjusting their design to make sure that there was not too much pressure being applied to the baby’s face, that the strap securing the tube was the right thickness and that the materials they used were biocompatible and flexible to prevent skin irritation.

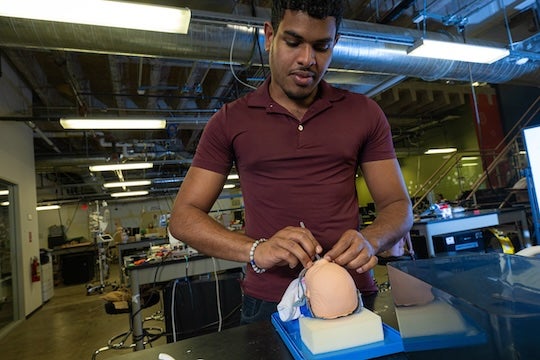

“The device we have come up with actually holds it all in place securely,” Majeti said. “We just went to Texas Children’s and had Jain test it. We were in a simulation lab that has this very expensive mannequin that is basically as realistic as you can get with a fake model with the baby. We tested our device by placing it on the mannequin, and despite vigorous shaking, the tube did not move at all. So I think the fact that we’ve got better attachment, better visualization and it’s in an overall cohesive package that we’re producing makes this a good project.”

(Photo by Jeff Fitlow/Rice University)

Dr. Chester Koh, professor at Texas Children’s Hospital, Baylor College of Medicine and Rice and executive director of the FDA-supported Southwest National Pediatric Device Innovation Consortium, noted, “These novel pediatric device projects at Rice address the unmet needs that our pediatric specialists have identified in the hospital and provide the opportunity to partner with these engineering teams to improve the care for our smallest and often fragile patients. Our consortium is honored to sponsor these projects each year.”

Ghayour, another senior on the team who plans to pursue medical studies after graduation, first started working on assembling and testing the anchoring system, then her role shifted to environmental testing.

“I would submerge our anchoring mechanism and the integrated tube into a simulated trachea environment and see how it would hold out,” Ghayour said. “This included force testing to characterize the durability of the anchor and creating a mucosal environment using the correct temperature range.”

For the ETT part of the device, the students had to make sure that the main tube had enough room to accommodate air flow while still being able to incorporate a light, camera and flush cord to clear secretions from the camera lens.

“I think our biggest challenge and success was getting all the components small enough to fit inside our integrated tube,” said Parthasarathy. “A regular tube requires repositioning if it’s misplaced, which can be tricky if the patient has a difficult airway.”

Currently, the only way to make sure that the breathing tube is correctly positioned on an intubated baby is using X-rays, which carries some risk and can be expensive.

“We wanted to find a way to be able to check that breathing tubes were in the correct place in the baby’s airway without having to basically sting them with X-rays and without having to jostle them around that much,” Philip said.

Visibility is especially important for patients 6 months and younger because their anatomy can be difficult to navigate.

“No ETTs sized for pediatric patients enable the person intubating to see inside the body during the procedure, but our device makes that possible,” said Pearce, who plans on pursuing a doctorate in optical and computational imaging after graduation. Together with Balakrishnan, Pearce performed market reviews and testing to identify a camera that best fit the needs of the project and the right accompanying LED.

For Less, the project served as a way to delve into an unfamiliar area of engineering and “see what a mechanical engineer could do in the pediatric medical device world.”

“I did go in blind, but I learned a lot,” Less said.