University Of Bristol Experts Develop Sponge That Improves Robotic Grasp

A simple sponge has improved how robots grasp, scientists from the University of Bristol have found.

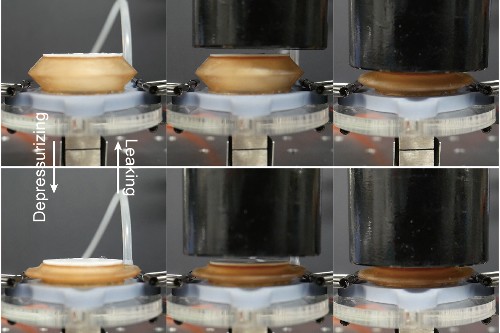

This easy-to-make sponge-jamming device can help stiff robots handle delicate items carefully by mimicking the nuanced touch, or variable stiffness, of a human.

Robots can skip, jump and do somersaults, but they’re too rigid to hold an egg easily. Variable-stiffness devices are potential solutions for contact compliance on hard robots to reduce damage, or for improving the load capacity of soft robots.

This study, published at the IEEE International Conference on Robotics and Automation (ICRA) 2023, shows that variable stiffness can be achieved by a silicone sponge.

Lead author Tianqi Yue from Bristol’s Department of Engineering Mathematics explained: “Stiffness, also known as softness, is important in contact scenarios.

“Robotic arms are too rigid so they cannot make such a soft human-like grasp on delicate objects, for example, an egg.

“What makes humans different from robotic arms is that we have soft tissues enclosing rigid bones, which act as a natural mitigating mechanism.

“In this paper, we managed to develop a soft device with variable stiffness, to be mounted on the end robotic arm for making the robot-object contact safe.”

Silicone sponge is a cheap and easy-to-fabricate material. It is a porous elastomer just like the cleaning sponge used in everyday tasks.

By squeezing the sponge, the sponge stiffens which is why it can be transformed into a variable-stiffness device.

This device could be used in industrial robots in scenarios including gripping jellies, eggs and other fragile substances. It can also be used in service robots to make human-robot interaction safer.

Mr Yue added: “We managed to use a sponge to make a cheap and nimble but effective device that can help robots achieve soft contact with objects. The great potential comes from its low cost and light weight.

“We believe this silicone-sponge based variable-stiffness device will provide a novel solution in industry and healthcare, for example, tunable-stiffness requirement on robotic polishing and ultrasound imaging.”

The team will now look at making the device achieve variable stiffness in multiple directions, including rotation.