University of Toronto prof uses virtual reality to beam engineering lab into students’ homes

For more than 70 years, the Unit Ops Lab at the University of Toronto’s Faculty of Applied Science & Engineering has been a cornerstone for undergraduate training in chemical engineering.

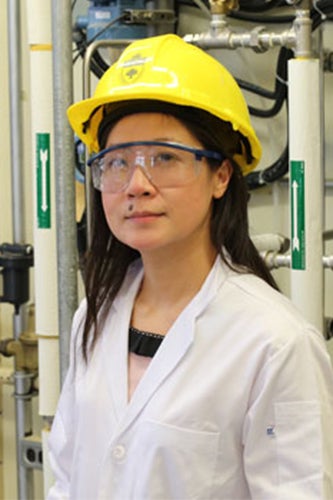

Now, Ariel Chan, an assistant professor, teaching stream, in the department of chemical engineering and applied chemistry, is using virtual reality and 3D simulations to make the lab accessible to students who are studying remotely during the COVID-19 pandemic.

“Unit Ops is like medical school for our students,” says Chan, who co-ordinates several lab-based courses built around the facility’s capabilities. “It’s such a major lab, providing students with the practical experiences of an experienced engineer.

“Only a handful of universities in Canada have a facility like this.”

The two-storey laboratory space is located in the Wallberg Building. It features towering industry-scale equipment and provides third-year students with hands-on experience. Unit Ops is where they design and experiment with processes used in a wide range of chemical engineering industries, from bioethanol production to pharmaceutical drug manufacturing.

“Sadly, this term students are missing the opportunity to experience it [in person], to go up and down those stairs – but we can do our best to get it as close as we can, and bridge that curriculum gap,” Chan says.

While students won’t have the opportunity to walk up and down the two-storey lab’s staircase, Ariel Chan says the combination of VR, high-resolution virtual tours and at-home experiments gives students the opportunity to test their skills in an industry environment.

Chan and her teaching assistants are mimicking the Unit Ops experience using VR, high-resolution virtual tours, at-home experiments and 3D simulation/design software. Together, the tools give students a chance to virtually step into the Unit Ops Lab and test their skills in an industry environment.

Using the VR program Labster, students experience a first-person point of view as they replicate an industry-style lab experiment – even putting on a lab coat and gloves.

Students then refer to the Unit Ops website Chan and her team created exclusively for students. The site allows students to connect the dots between what they handled in the virtual lab and what those same pieces of equipment look like within the Unit Ops lab space.

“The team mapped out every inch of the lab to create a fully immersive and comprehensive virtual experience of Unit Ops,” says Chan.

Students are also given pre-collected data that they can compare to similar systems within their household. For example, a regular household drainage pipe can serve as a scaled-down example for studying the upstream and downstream processes of bioethanol production.

A user is instructed to don gloves during a VR experiment in Labster.

“The guiding philosophy for our approach is that engineering is all around us,” says Chan. “If [the students] were [working] in industry, they would have to inspect piping systems to figure out the cause of a blockage. That’s not too different from inspecting your sink pipes.”

The home lab component turns the online instruction into practical learning – whether it’s experimenting with yeast fermentation to learn bioethanol production or studying a kitchen stove to assess heat-transfer effectiveness.

“Sure, you can learn the chemistry, the measurements – but when you turn a valve, how does it feel? The sensory portion is so important,” says Chan.

To ensure students approach each assignment like a practising engineer, they are asked to design a 3D simulation of the system they’re studying and perform the experiment as if they were in industry.

The approach seems to be resonating with students. During the fall term, many shared their home experiments and video presentations on the course’s message boards – and even on TikTok.

“When you do more, and for the greater good, it’s rewarding,” Chan says. “Other universities might just give students data and an assignment, but for our students, the extra work – this whole process – enables them to be better prepared to be engineers.”