Unlocking industrial resource productivity through sustainability – energy, material and water efficiency”; 2nd CII Business Sustainability Summit

New Delhi: The conference on Business Sustainability was organized by CII on September 23-24, 2021 on virtual mode in a wide range of topics related to the theme. Delegates and speakers included academicians, researchers, consultants, activists, corporate managers and bureaucrats.

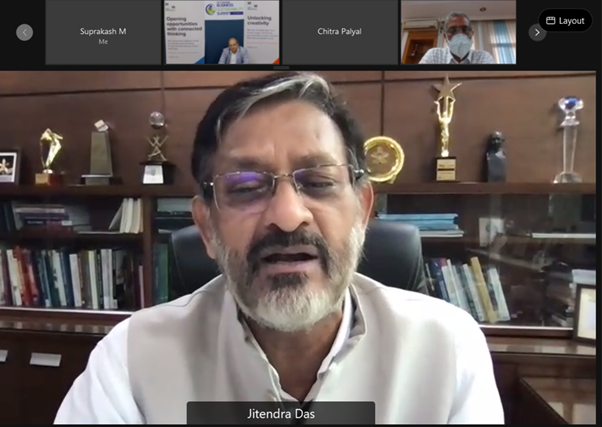

Dr. Jitendra K. Das, Director, FORE School of Management, New Delhi, who was the moderator of session, “Unlocking industrial resource productivity through sustainability – energy, material and water efficiency”, talked about the challenges of sustainability, material and water efficiency; carbon footprints and ecosystem stating how ecosystems work while remaining interconnected and dependent on other ecosystems.

“Larger sustainable business models and best practices should be in place which brings in environmental and societal changes”, he said.

Along with Dr. Das, eminent speakers, Mr. Saroj Banerjee, Chief-Environment Tata Steel BSL Ltd; Mr. A. P. Abraham, Head-Operations, Continental Carbon India Private Limited and Mr. Ashish Mistry, Industry Sector Leader, Mott McDonald India, were panelists.

“In any type of production process, a lot can be done at variable cost components like in managing the water consumption along with materials, energy. A lot can be achieved only by inculcating the thought of water consumption, recycling of water, turning-off when not in use. This also brings down variable cost and improves profitability”, added Dr. Das.

Citing an example of consumptions and profitability, Mr A P Abraham, Head-Operations Continental Carbon India Private Limited, said, how his plant has been generating power upto 15 MW from the waste material, which earlier used to happen from gases. Not only has the usage of gas been stopped but the surplus power generated is shared with Uttar Pradesh (UP) Grid. “We reduced Co2 from the environment and generated 15 MW Green power, green steam to MSME, 27% of total water requirement from recycled water cycle,” he added.

Mr. Ashish Mistry talked about ‘Unlocking productivity through Sustainability energy, material and water efficiency’, while also stressing upon renewable energy, waste management and green supply chain management. He also touched upon optimal material utilisation, appropriate equipment sizing, capturing material flow and cutting down on cause of wastes and emissions, reducing batch cycle time, recycling waste material, using automatic systems.

Mr. Mistry listed out valuable pointers for targeting efficiency in water – reduce, reuse, recycle, conserve and replace.

Reduce – Audited water balance

Reuse: Reuse of process water

Recycle – Zero liquid discharge

Conserve – Rain water harvesting

Replace – Air cooled equipment instead of water cooled equipment.

Mr Saroj Banerjee, Chief Environment, Tata Steel BSL Limited, spoke about sustainability in waste materials, including minimising Co2 emissions by utilizing 100% blast furnace slag in cement production and avoiding fugitive air emissions during transportation. He mentioned that TATA Steel BSL Limited is the 1st Indian company to implement an internal carbon pricing in the financial appraisal of capital project.