Small wearable or implantable electronics could help monitor our health, diagnose diseases, and provide opportunities for improved, autonomous treatments. But to do this without aggravating or damaging the cells around them, these electronics will need to not only bend and stretch with our tissues as they move, but also be soft enough that they will not scratch and damage tissues.

Researchers at Stanford have been working on skin-like, stretchable electronic devices for over a decade. In a paper published March 13 in Nature, they present a new design and fabrication process for skin-like integrated circuits that are five times smaller and operate at one thousand times higher speeds than earlier versions. The researchers demonstrated that their soft integrated circuits are now able to drive a micro-LED screen and detect a braille array that is more sensitive than human fingertips.

“We’ve made a significant leap forward. For the first time, stretchable integrated circuits are now small enough and fast enough for many applications,” said Zhenan Bao, a K. K. Lee Professor in Chemical Engineering at Stanford and senior author on the paper. “We hope that this can make wearable sensors and implantable neural and gut probes more sensitive, operate more sensors, and potentially consume less power.”

Flexible, stretchable, and functional

The core of the circuits are stretchable transistors made from semiconducting carbon nanotubes and soft elastic electronic materials developed in Bao’s lab. Unlike silicon, which is hard and brittle, the carbon nanotubes sandwiched between elastic materials have a fishnet-like structure that allows them to continue to function while they stretch and deform. The transistors and circuits are patterned onto a stretchable substrate, along with stretchable semiconductor, conductor, and dielectric material.

“This is many years of material and engineering development,” Bao said. “We not only needed to develop new materials, but we also needed to develop the circuit design and the fabrication process to make the circuits. There are many layers stacked together and if one layer doesn’t work, we have to restart everything from scratch.”

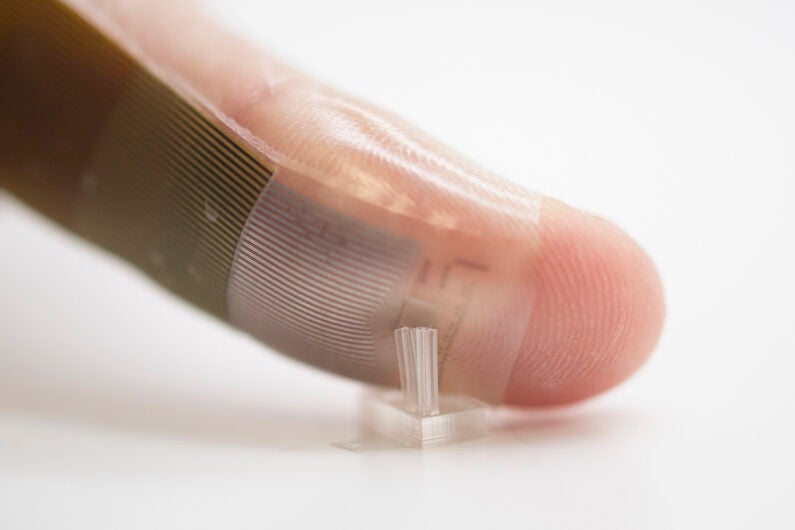

In one demonstration of their new stretchable electronics design, the researchers were able to fit more than 2,500 sensors and transistors into a square centimeter, creating an active-matrix tactile array over ten times more sensitive than human fingertips. The researchers showed that the sensor array can detect the locations and orientation of tiny shapes or recognize whole words in Braille.

“With Braille, you usually sense one letter at a time,” said Donglai Zhong, a postdoctoral researcher in Bao’s lab and co-first author on the paper. “With such a high resolution, you could sense a whole word, or potentially a whole sentence, with just one touch.”

The researchers also used their stretchable circuits to drive a micro-LED display with a refresh rate of 60 Hz, which is the typical refresh rate of a computer or TV screen. Previous versions of the stretchable circuits weren’t fast enough at small sizes to generate enough current to accomplish this.

“We’re really excited about these performance improvements because they enable us to do a lot of new things,” said Can Wu, a postdoctoral researcher in Bao’s lab and co-first author on the paper. “Preliminary results demonstrate that our transistor can be used to drive commercial displays commonly used in computer monitors, for example. And for biomedical applications, a high-density, soft, and conformable sensing array could allow us to sense human body signals, such as from our brains and muscles, at a large scale and fine resolution. This could lead to next-generation brain-machine interfaces that are both high-performance and biocompatible.”

An active-matrix sensor array attached to a human finger. (Image credit: Donglai Zhong and Can Wu of Bao Group in Stanford University)

Soft circuits for the future

The researchers intentionally developed materials and processes that could work with existing fabrication tools, so that the circuits could make the jump to commercial manufacturing more easily. Their process relies on fabrication techniques similar to what is currently used for making display screens, although the materials involved are entirely different. Manufacturers wouldn’t be able to make these circuits without some additional fine-tuning, but the tools are already in place, Bao said.

Of course, there are more hurdles before these stretchable and soft integrated circuits can be ready for commercialization. Body and tissue movement can still cause some variation in the electrical characteristics of the circuits – Bao and her colleagues are working on new designs that could reduce these effects – and the devices will need some sort of soft moisture protection before they can be put to use.

“There are still challenges for the future of this technology, but these recent developments open up some very exciting biomedical applications for wearable and implantable electronics,” Bao said. “And it also has applications in soft robotics, giving robots a sensing functionality that approaches that of humans and makes them safer for people to work with.”